UV Printing

Speed, versatility and profits with direct-to-object printing

What is UV Printing?

The Smart Way to Print Direct-to-object

UV printing is one of the most flexible and exciting direct-to-object print processes ever created, and its uses are almost limitless. The benefits of UV printing include:

- fast production with instant ink curing

- the capability to print directly on a wide range of materials

- and the ability to print 3D textures, effects and gloss highlights.

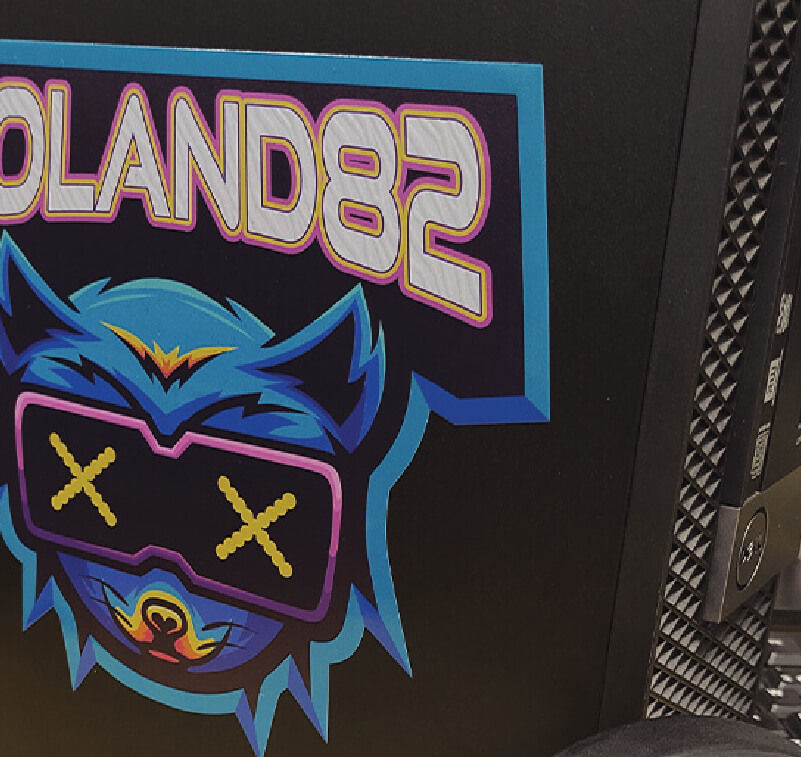

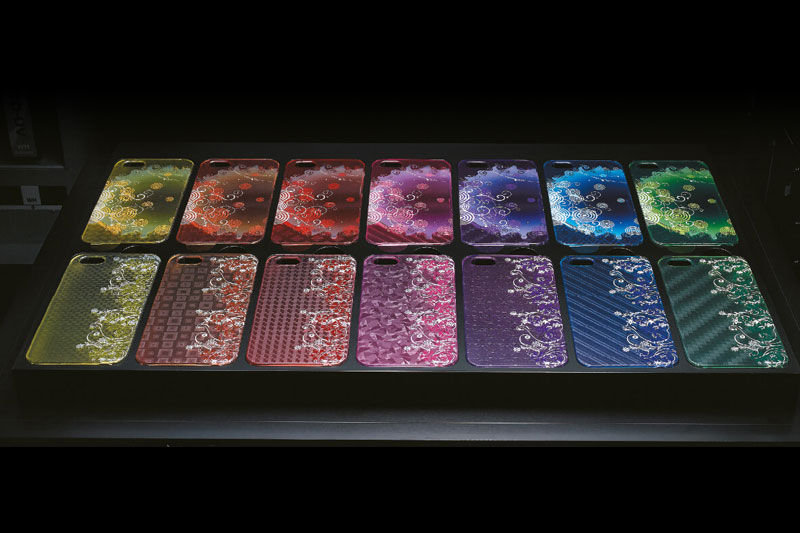

Using UV printing technology, you can print custom designs, images, text and even textures directly onto a vast range of materials or products.

What Can You Make with UV Printing?

If you can think of it, you can create it with UV print

How Does UV Printing Work?

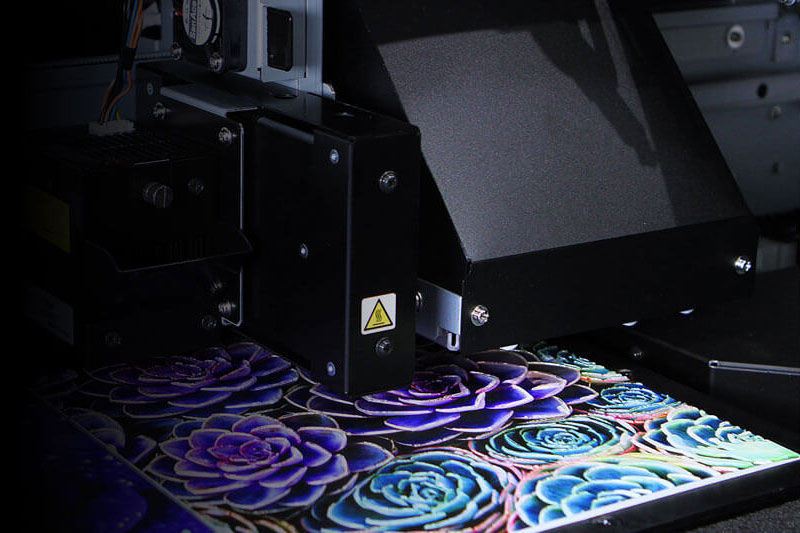

UV digital printing speeds up the print production process by instantly curing specially formulated UV inks on a vast range of materials using UV lamps.

Piezo print heads eject ink with precision onto the print media. This technology gives you control over the print quality, colour density and finish.

The ink is instantly cured during printing, meaning you can produce more, faster, with no drying times and ensure a high-quality, durable finish.

LED lamps are long-lasting, ozone-free, safe, energy-efficient and cost-effective. Their low temperatures let you print on heat sensitive materials.

Making a Profit

The Fast Way to Get a Return

The simplicity and speed of UV print technology lets you produce more with greater flexibility and lower overheads than traditional screen or pad printing processes.

This lets you offer your customers more options to customise their products without impacting your workflow or profitability.

Making it Interesting

Print Onto Almost Anything

You can print on a huge range of material with UV print. Since the ink is cured instantly, it isn’t absorbed and doesn’t not etch, damage or react with the media. Also, with low curing temperatures, you can print on heat-sensitive materials.

With this capability, you can extend your product catalogue to include items made from wood, glass, ceramic, leather, canvas or metal, as well as a wide range of plastics.

Making an Impact

The Fast Way to Get a Return

The simplicity and speed of UV print technology lets you produce more with greater flexibility and lower overheads than traditional screen or pad printing processes.

This lets you offer your customers more options to customise their products without impacting your workflow or profitability.

Customer Testimonials

Succeeding with Roland DG UV Printing

Find the right UV print solution for you

Frequently Asked Questions

Can you UV print on fabric?

You can UV print onto most fabrics if they can be placed flat on the bed, but it is not recommended for garments which may come into contact with skin. In all cases, it’s recommended to test any substrate to ensure the best results.

How can I UV print on acrylic?

Printing on acrylic sheets or block is similar to printing on any other flat surface – simply place the item on the bed, set up your artwork in the RIP and start printing. You may wish to mask the sides of acrylic blocks to prevent overspray.

How long does UV printing last?

A UV print will typically last at least 2 years without fading, and with lamination, this can be even longer.

What is spot UV in printing?

Spot UV is a term used to describe the application of a clear ink for highlighting elements of the design. This creates an eye-catching, glossy finish in specific areas, for example on logos or text.

Is UV printing environmentally friendly?

Because the ink is cured instantly at low temperatures, UV printers use much less energy than other technologies which rely on heat to dry the ink. Also, the lamps require no warm-up time, which reduces standby consumption when not in use.

Why Choose Roland DG?

People buy Roland DG equipment because they know it will do what they need it to do - and more. Our mission is to bring new opportunities to society through digital technology, and we aim to develop the most reliable solutions in the industry.

- More than 40 years of trusted technical excellence.

- Robust, flexible technology and repeatable results.

- Unparalleled post-sales service and support.

Get in touch today and find out why Roland DG is the first choice for print businesses worldwide.