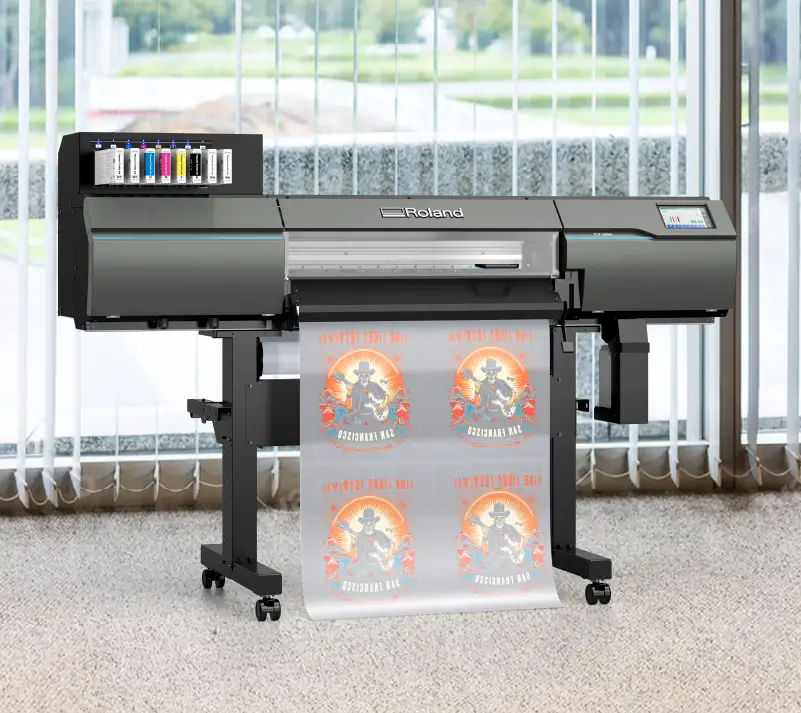

DTF Printing for

Real Production

Continuous operation. Exceptional results.

NOW WITH DOUBLE WHITE INK

The dependable DTF printer built for real production.

NEW TY-300i Direct-to-Film Printer

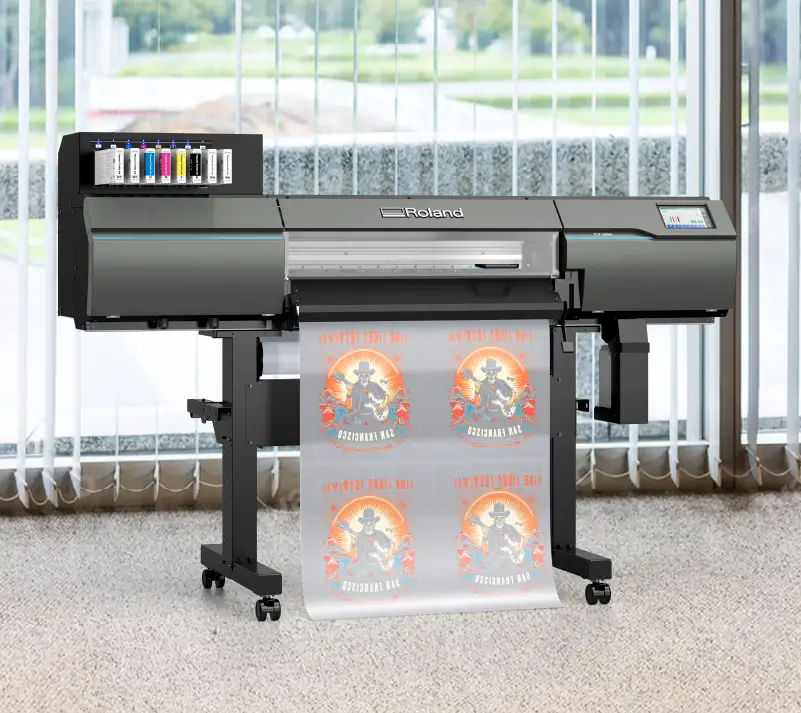

You care about producing work that looks exceptional. The TY-300i helps you achieve it with richer colour, stronger detail and more consistent results than other DTF systems. Faster output and expanded white capacity keep production moving, even on demanding days.

It is a complete Roland DG DTF setup with premium inks and powder, backed by the reliability and support you can build your reputation on.

Run longer. Print sharper. Deliver more.

Your Complete Roland DG DTF Workflow

You want transfers you can trust, shift after shift. TY-300i sits at the heart of a complete Roland DG DTF setup, combining the TY-300i DTF printer with VersaWorks RIP, premium Roland DG inks and powder, and Roland DG Care support to keep colour, detail and uptime consistent. It also integrates with compatible shaker and dryer units to automate the powder stage and sustain high-volume production.

Professional DTF Printing for Every

Apparel and Fabric Application

Built for Consistent, Commercial-Grade DTF Production

Powerful Performance.

Maximum Productivity.

The TY-300i delivers exceptional CMYK + White performance, printing at up to 10.9 m²/h in standard mode and 17.48 m²/h in high-speed mode, as much as 45 percent faster than comparable DTF printers tested.

This increased throughput supports continuous production and reduces the need for operator intervention, helping you meet high-volume demand with confidence.

Print with Precision.

The TY-300i delivers vivid, accurate colour and fine detail across a wide range of fabrics. Internal testing shows smoother gradients and stronger solids than other printers in its class, maintaining bright whites and consistent tone from print to print.

Certified Safety and

Ink Confidence.

Roland DG’s S-PG2 inks and powder are OEKO-TEX® ECO PASSPORT certified and REACH compliant, giving you full confidence when producing apparel for retail.

The inks deliver consistent results while supporting safe, sustainable DTF production that meets the standards your customers expect.

Simplified Maintenance.

Continuous Reliability.

Designed for everyday reliability, the TY-300i simplifies routine maintenance with guided cleaning sequences and improved white-ink circulation.

Components are easily accessible, helping operators keep production running smoothly with less downtime and predictable day-to-day performance.

Outstanding

Wash Durability.

The TY-300i delivers prints that stay bright and crack-free after 50 wash cycles in internal testing, outperforming comparable DTF models evaluated.

Strong colour stability and reliable white adhesion help your garments maintain their premium finish long after they reach the customer.

WINNER

Keypoint Intelligence BLI Pick Award 2026

The TY-300i delivered an exceptionally strong overall performance in our testing. Its image quality was consistently impressive. These results position the TY-300i as a formidable competitor in the rapidly expanding direct-to-film market.

—David Sweetnam, Director of Lab Services, Keypoint Intelligence

Protect Your Investment

Take your business forward with complete peace of mind thanks to Roland DG’s renowned post-sale service. Roland DG Care warranties cover you for much more than device maintenance.

- Factory-trained service engineers

- Quick installation and first-time set-up

- Expert advice and training.

- Genuine Roland DG parts and accessories

Additional Information

Datasheet

Download Your TY-300i Datasheet

Get your digital guide to all the features, applications, benefits and specifications of the Direct-to-Film Printer.

Download DatasheetSpecifications

| TY-300i | ||

|---|---|---|

| Printing Method | Piezo ink-jet method | |

| Media | Width | 182 to 762 mm (7.2 to 30 in) |

| Thickness | Maximum 1.0 mm (39.3 mil) with liner for printing, Maximum 0.4 mm (15.7 mil) with liner and 0.22 mm (8.6 mil) without liner for cutting | |

| Roll outer diameter | Maximum 250 mm (9.84 in) | |

| Roll weight | 30 kg (66.1 lb) | |

| Core diameter | 76.2 mm (3 in) or 50.8 mm (2 in) | |

| Printing/cutting width (*1) | Maximum 736 mm (28.9 in) | |

| Ink | Type | S-PG2 INK 500 ml cartridge |

| Colours | Five colours (cyan, magenta, yellow, black, and white) | |

| Printing resolution | Maximum 1,200 dpi | |

| Cutting speed | 10 to 300 mm/s (0.39 to 11.8 in/s) | |

| Blade force (*2) | 30 to 500 gf | |

| Blade type | CAMM-1 series blade | |

| Blade offset | 0.000 to 1.500 mm (0.0 to 59 mil) | |

| Software resolution (cutting) | 0.025 mm/step (0.98 mil/step) | |

| Media heating system (*3) | Print heater set temperature: 30 to 38°C (86 to 100°F), Dryer set temperature: 30 to 45°C (86 to 112°F) | |

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | |

| Power-saving function | Automatic sleep feature | |

| Rated input | 100-120 / 220-240 Vac 50/60 Hz 6.4/3.0 A | |

| Power consumption | During operation | Approx. 840W |

| Sleep mode | Approx. 70W | |

| Acoustic noise level | During operation | 63 dB (A) or less |

| During standby | 58 dB (A) or less | |

| Dimensions (Width x Depth x Height) | 2,032 mm x 748 mm x 1,415 mm (80 in x 29.5 in x 55.8 in) | |

| Weight | 136 kg (300 lb.) | |

| Environment | During operation (*4) | Temperature: 20 to 28°C (68 to 82.4°F), Humidity: 40 to 60% RH (no condensation) |

| Not operating | Temperature: 5 to 40°C (41 to 104°F), Humidity: 20 to 80% RH (no condensation) | |

| Included Items | Dedicated stand, Power cord, Media holders, Separating knife, Replacement blade, Cleaning liquid, Drain bottle, User's Manual, Software(VersaWorks, Roland DG Connect), etc. | |

| *1 | The length of printing or cutting is subject to the limitations of the program. |

| *2 |

|

| *3 |

Warm-up is required after power up. This may require 5 to 20 minutes, depending on the operating environment. Depending on the ambient temperature and media width, the preset temperature may fail to be reached. |

| *4 | Operating environment (Use in an operating environment within this range.) |

|

|