UV-LED printing has become hugely popular in the last decade thanks to its instant, low-temperature curing and its ability to print highly durable designs onto almost any substrate.

One of the other key benefits of UV printing is the addition of gloss or clear ink. When printed and cured, this special ink takes on a rigid, 3D appearance. This simple functionality unlocks new print effects, textures and capabilities which can enhance printed products and ultimately generate more profit.

Let’s look at some of the things you can do with gloss UV ink.

What Can You Do with Gloss Ink?

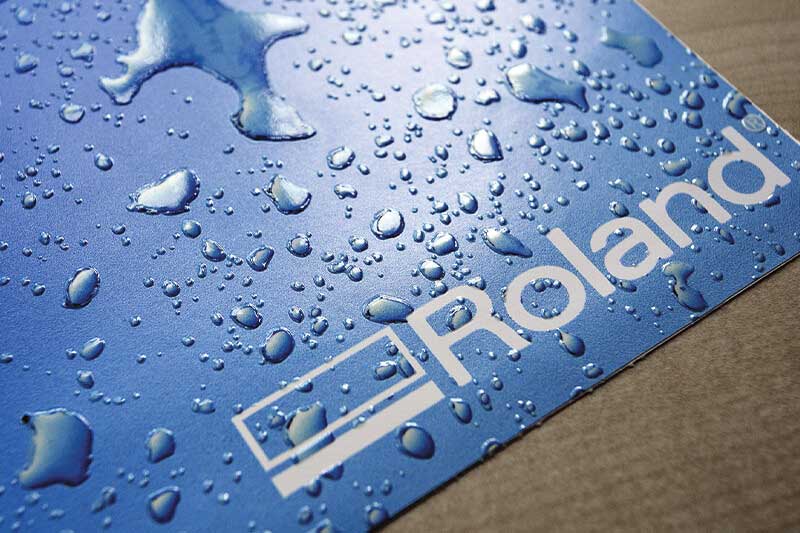

Printing Spot UV Highlights

Pictured: Clear gloss ink used to create realistic water droplets. One of the simplest uses of gloss ink is to highlight important areas of the design with an eye-catching gloss varnish effect. This spot UV technique is particularly useful if you want to call attention to text containing an important promotional message or to draw attention to a logo. It can also be used very effectively to highlight liquids like water droplets, giving a realistic effect.

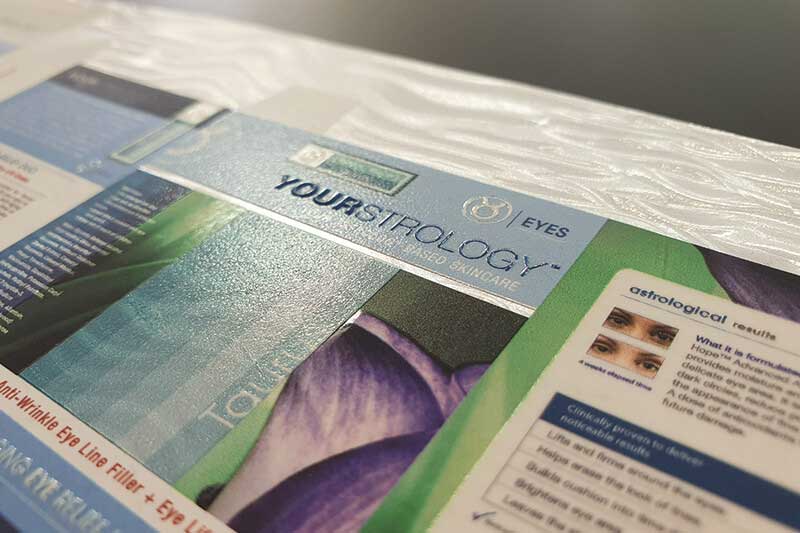

Printing Embossed and Debossed Effects

Pictured: Embossed text simulated with gloss UV ink on packaging mock-up. At the level of mass production, embossed effects require a custom-made die or stamp. When it comes to smaller runs or packaging mock-ups, it’s prohibitively expensive to recreate this effect using the same method. This is part of the reason why UV printing has become very popular in the field of packaging prototypes and design, offering the ability to produce a convincing embossed effect quickly and at a low cost.

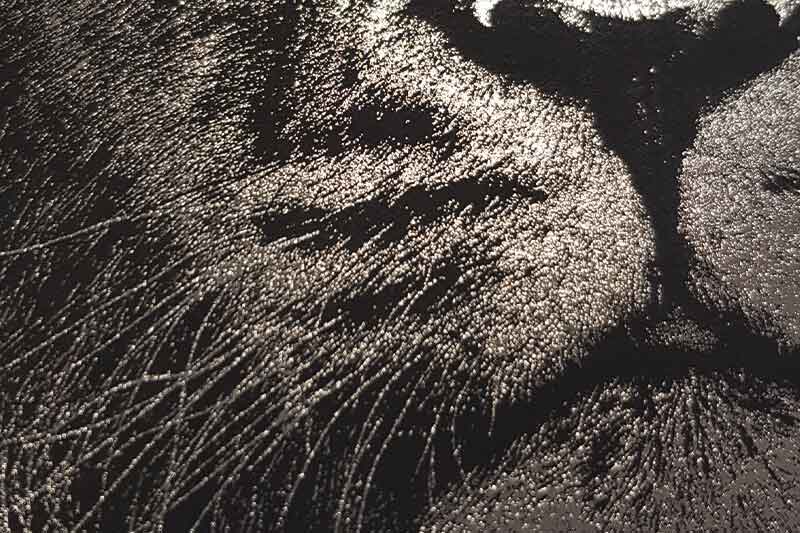

Printing Texture Effects

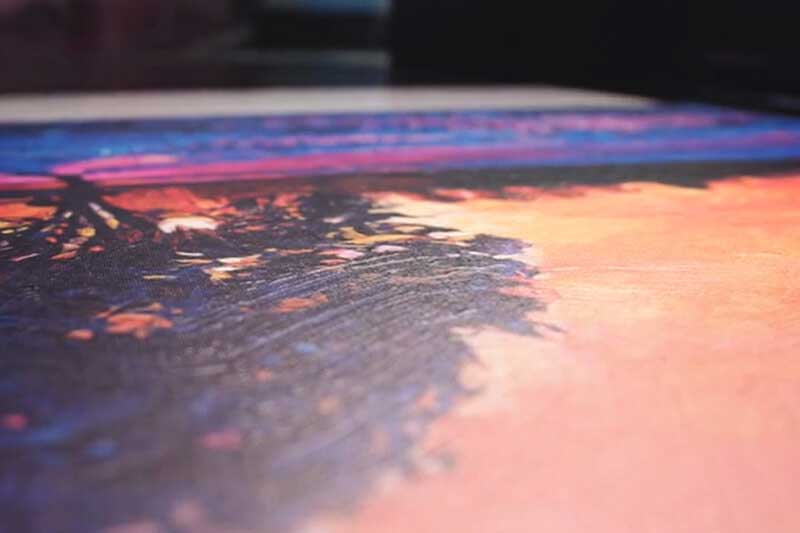

Pictured: Woodgrain texture generated with gloss UV ink on haptic proof. It’s also possible to build up layers of gloss ink to generate realistic printed textures for a variety of products. For example, you can print an animal skin texture for luxury items or print a wood-grain texture for haptic proofs used in interior design. You can even use it to produce an attractive oil painting complete with textured brush strokes.

Cold Foiling

Fine detail generated with foil using gloss UV ink. Like embossing, foil effects require expensive additional tools at an industrial level. Once again, gloss UV ink can reproduce a similar effect with a much lower cost and a more flexible workflow. With this process, the gloss ink is only partially cured, providing an adhesive surface to which foil is then laminated. Once completed, it’s possible to generate extremely fine details using metallic foil or similar materials like glitter.

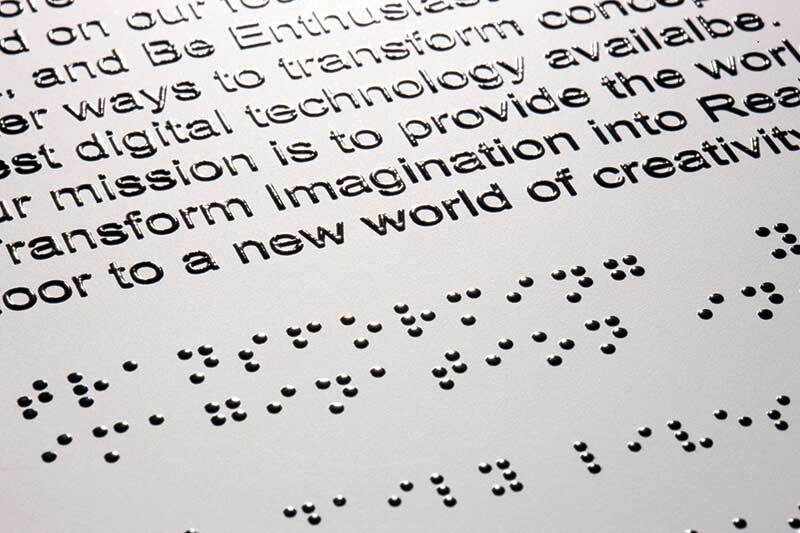

Printing Braille

Pictured: Braille text added to signage with gloss UV ink. Braille arguably holds the greatest profit-making potential, particularly for businesses who specialise in signage. Traditional methods are costly and usually require outsourcing this stage to a third party, thereby lengthening the lead time. With gloss ink, it’s relatively easy to create Braille signs and stickers by adding an additional gloss layer in the artwork containing the Braille data.

How It Works: Creating A Realistic Oil Painting

So, what does a gloss project look like in practical terms? Provided you have an intuitive and fully functional RIP, all you really need is some design software like Adobe Illustrator. We will look at producing a brushstroke texture on an oil painting, but the process is quite similar for all gloss ink applications.

Pictured: Oil painting printed direct to canvas with brushstroke texture.

Designing the Gloss Layer

This is the most complicated part of the project, and it’s really quite straightforward. For most RIPs, you will need to assign a spot colour to designate where the gloss ink should go. If you are using Adobe Illustrator, for example, all you need to do is to ensure your gloss shapes are filled with the required spot colour.

How Gloss Thickness is Defined

In general, the thickness of the gloss section is defined by the opacity of the colour. If you wanted to create a smooth dome, you would create a radial gradient with the opacity of the colour reducing as it approaches the edge of the shape. If you don’t do this and you give the entire shape an opacity of 100%, the gloss effect will drop off abruptly at the edge of the shape.

Working with Raster Images

It’s usually easier to work with vector shapes when creating a gloss layer. In the case of our oil painting, we have used a raster image containing a brushstroke pattern. Converting this to gloss data is relatively simple when using Adobe Illustrator. Simply convert the colours of the image to greyscale and set the fill colour to the gloss spot colour. Again, wherever the image is darkest, more gloss ink will be printed. If this doesn’t suit the effect you wish to achieve, you can invert the colours.

Looking for More?

Do you want to add spot UV capability to your business? Get in touch with a Roland DG expert and they’ll happily talk you through your options and show you examples of the things you could do with gloss UV ink.