One sportswear company reinvents itself and launches a new brand of masks.

Inverse | Spain

Many companies have got to rethink their business to overcome the current situation. This is the case of Inverse, a company with a long history in the production of sportswear personalisation, which after spending a few weeks collaborating in the manufacture of face masks to fight the COVID-19, decided to create its own range of reusable protective masks.

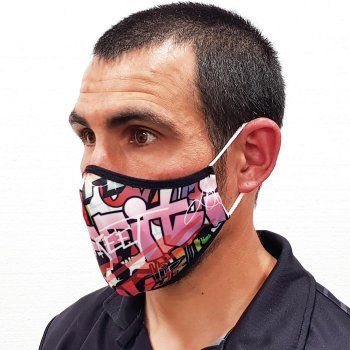

In response to the sales decrease in sports articles and aware of the new paradigm caused by the COVID-19, they reinvented their business to meet new needs. So, they launched a new brand, WindFlap, focused exclusively on the production of customised masks with eye-catching and original designs.

The new brand took advantage of Inverse expertise in the sportswear industry, its technology and its design knowledge, to quickly adapt the products to the tastes of their clients.

From customised corporate masks for companies, to masks much more creative. Furthermore, aware of the new needs, the company has created a special line for children with three different sizes that adapt according to age (from 3 to 5 years, from 6 to 9 years and from 9 to 12 years). These masks adapt perfectly and use much brighter colors that surprise and capture the attention of children.

Also, it is important to highlight that all these products are certified with the new UNE 0065:2020 regulation on reusable hygienic masks.

The process of customising masks is as easy as customising sportswear. Using textile sublimation technology, the same technology that Inverse already uses for its garments, they add the designs to the masks. Thanks to Roland's Texart XT-640, a dye-sublimation printer that delivers outstanding print quality and speed on long print runs, they can print from a single piece to much longer runs with different designs. With its rugged construction and staggered print heads, the XT-640 is built to meet the most demanding production and quality requirements, in both speed and quality.

The masks are available online. They have already sold 19,000 units and have started to receive orders.

Inverse has managed to take advantage of its strengths to successfully adapt to a new situation. Until the sports sector reactivates at its usual activity, the company has found in the personalisation of masks a way to overcome the crisis.

Find more information about Inverse and Wind Flap on their websites.