Intuitive and Intelligent

Engraving

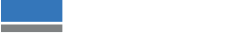

DE-3 Desktop Engraver

-

LIST PRICE

Starting from £ 5,450

The DE-3 desktop engraver uses over 30 years of innovation in engraving technology to deliver impressive versatility and fast, user-friendly automated production.

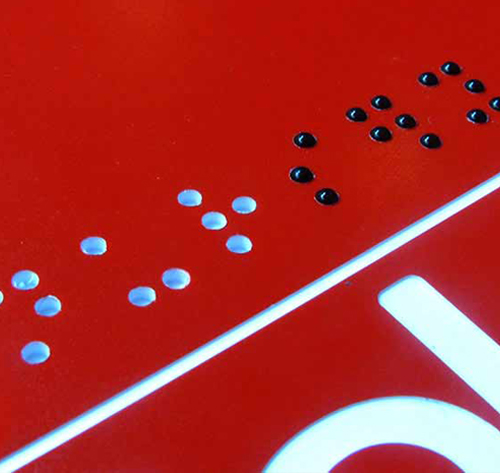

With laser-pointing technology, automatic depth regulation and other intelligent and intuitive features, the DE-3 produces precise text and graphics onto a huge range of materials and objects. It's the ideal desktop engraving solution for today's user.

Download Brochure

Discover A World of Engraving Applications

Whether you are a sign-maker, equipment manufacturer or awards and gift supplier, the DE-3 desktop engraver is the ideal solution for engraving an impressive variety of giftware, signage, trophies, tools and industrial products. The DE-3’s integrated safety cover and user-friendly operation also make it ideal for use in retail settings.

High Performance Features

Accurate Personalisation

A laser pointer accurately defines the origin point and displays an engraving path preview on the media – set the engraving position at the touch of a button.

Precision Engraving

Easy-to-apply nose cones can be added to the spindle unit to automatically regulate engraving depth on the media surface, delivering consistently precise results.

Fast and Easy Production

Powered by a 20,000 rpm DC brushless motor, the DE-3 harnesses advanced surface detection and other automatic features to make set-up and engraving quick and simple.

Remote Connectivity

Select options such as spindle speed and one-touch machine cleaning without the need for a computer with a hand-held control. Engraving job data can be sent from your computer and stored in the controller after the PC is disconnected.

* DE-3 shown with optional centre vice

New Software and Open Architecture

The DE-3 uses open source technology that works out-of-the-box with all popular engraving software, industry standard tools and materials. The engraver also comes with Dr. Engrave Plus software that offers a number of additional advantages to the user.

- AI files are now supported along with other standard graphic/vector data

- Standard text engraving, surface levelling and hole drilling are now possible thanks to new levelling

and drilling functions - Includes handy template functions and Excel and CSV databases for fast engraving of serial data jobs

Additional Benefits

| A compact desktop device with production-class engraver performance. | |

| An optional centre vice will hold irregular objects such as hip flasks, compact mirrors, spectacle frames and more securely in place. |

|

Boasts a small footprint with a generous 305 mm (X) x 230 mm (Y) x 40 mm (Z) work area that fits comfortably into office, classroom, workshop |

|

| A clean and safe engraving solution with a fully-enclosed engraving operation. |

Specifications

| Model | DE-3 | |

| Work table size | 305 mm x 230 mm | |

| Maximum work area (Work envelope) | X, Y, Z:305 mm × 230 mm × 40 mm | |

| XYZ axis drive system | Stepper motor, 3-axis simultaneous control | |

| Operating speed | XY axis: | 0.1-60 mm/sec. |

| Z axis: | 0.1-30 mm/sec. | |

| Software resolution | 0.01 mm/step | |

| Mechanical resolution | XYZ-axis: | 0.00125 mm/step |

| Spindle motor | Brushless DC Motor | |

| Spindle speed | 5000-20000 rpm | |

| Tool loading | Cutter Holder, Collet Type | |

| Maximum material thickness | 40 mm(38 mm when using the nose cone) | |

| Connection | USB | |

| Machine language | RML-1 | |

| Power supply | Voltage and frequency | AC 100 to 240V ±10%, 50/60 Hz (overvoltage category: II, IEC 60664-1) |

| Rated current | 1.0 A | |

| Power consumption | 80 W | |

| Operating noise | During operation | 60 dB(or less) |

| During standby | 40 dB(or less) | |

| External dimensions | 616 mm × 587 mm × 390 mm | |

| Machine weight |

35 kg |

|

| Installation environment | Indoor use, altitude: 2000 m or less, Temperature 5 to 40 °C, humidity 35 to 80% (no condensation), Environment pollution degree 2 | |

| Included items | DGSHAPE software package CD, Power cable, Power adapter, USB cable, Nose cone unit (resin / metal components), Nose unit set screw (fixing screw, spring), Spare set screw (for cutter holder), Solid collet (∅ 3.175 mm), Spanner wrench, Hex wrench, Hex driver, Adhesive sheet, Dust collector adapter, Setup Guide | |

Protect Your Investment

- Factory-trained service engineers

- Quick installation and first-time set-up

- Expert advice and training

Why Choose Roland DG?

People buy Roland DG equipment because they know it will do what they need it to do - and more. Our mission is to bring new opportunities to society through digital technology, and we aim to develop the most reliable solutions in the industry.

- More than 40 years of trusted technical excellence.

- Robust, flexible technology and repeatable results.

- Unparalleled post-sales service and support.

Get in touch today and find out why Roland DG is the first choice for print businesses worldwide.