MODELA MDX-50 Özellikler

Precision Milling on a Wide Range of Materials

The following items are just some of the materials that can be milled with the MDX-50 benchtop CNC mill:

POM

Nylon

Modeling Wax

PVC

Hardwood

Acetal

Mill Fine Details and Smooth Finishes

With an improved drive system, machine rigidity and enhanced drive mechanics, the MDX-50 mills incredibly smooth and accurate prototypes for testing structure, function, and assembly with other parts. A machining area of 15.8”(400mm) (X) x 12”(305mm) (Y) x 5.3”(135mm) (Z) supports production of large single objects or batch production of smaller multiple parts.

Mill Fine Details and Smooth Finishes

With an improved drive system, machine rigidity and enhanced drive mechanics, the MDX-50 mills incredibly smooth and accurate prototypes for testing structure, function, and assembly with other parts. A machining area of 15.8”(400mm) (X) x 12”(305mm) (Y) x 5.3”(135mm) (Z) supports production of large single objects or batch production of smaller multiple parts.

Free Your Time

The automated features of the MDX-50 enables users to mill with speed and confidence. Combine the 5-station ATC and optional rotary axis unit for the most automated and precise operation:

- Auto-sensing function corrects the tool length to ensure milling accuracy for every job

- Optional rotary axis for effortless production of complex surfaces:

- Includes a wide, self-centering headstock and tailstock workpiece clamps

- Auto-rotates materials from 0-to-360 degrees

- Indexes for 2-sided, 4-sided and custom angles

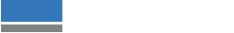

Built-in Control Panel

With a built-in control panel at the front of the unit, almost all operations can be completed from the unit itself. Users can perform operating functions and view the current job status without needing to constantly check their PC.

Simplified Machine Set-Up

The MDX-50 reduces the time and effort of machine set-up with an expanded work area, inner-machine lighting for clear visibility, and an included tool adopter that enables instant installation of ATC tools – requiring no wrench or additional tools.

Safe, Clean and Convenient Production

The MDX-50 is designed for use in studio and educational environments. A rail guided safety door ensures extra-safe operation while waste is contained in a built-in debris collection drawer.

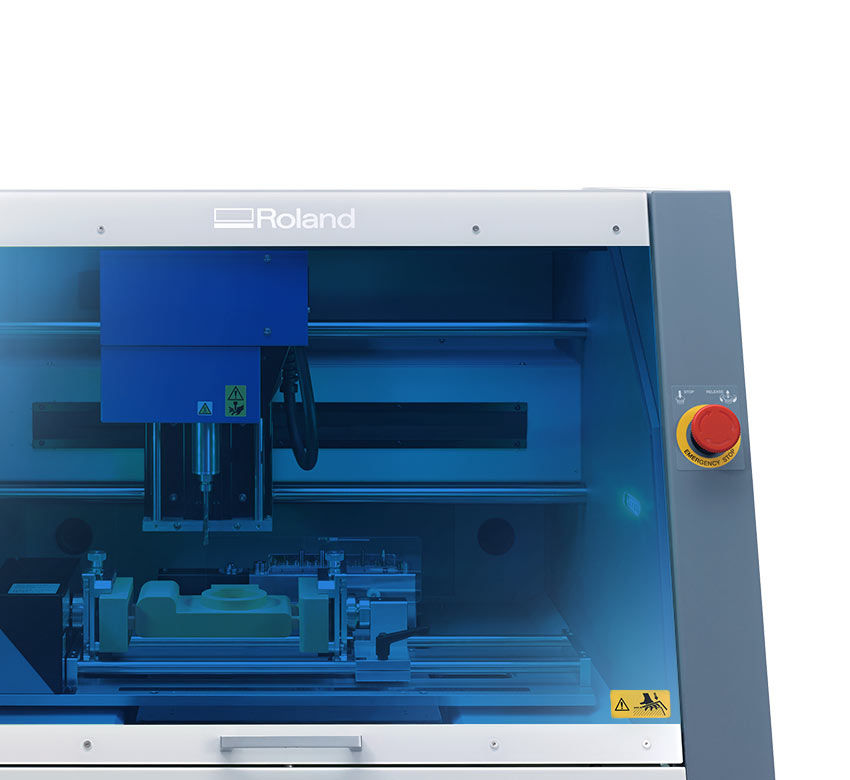

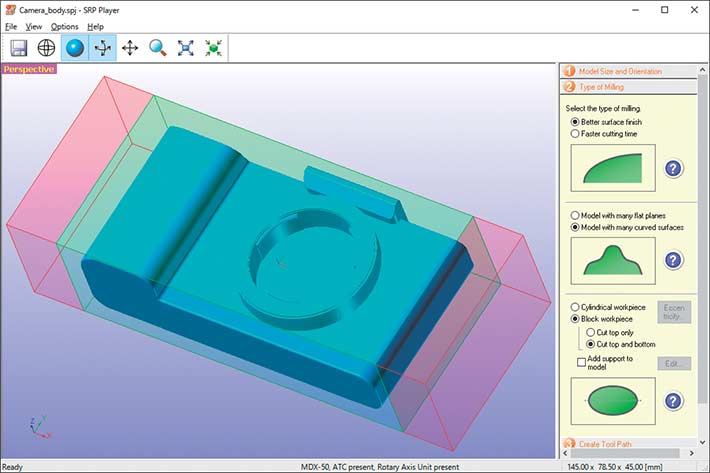

Included Software for Experts and Beginners

SRP Player CAM

The popular in Industry and Education software has been updated to match the advanced functions of the MDX-50. Milling settings can be configured in five simple steps, making operation straightforward even for those new to milling.

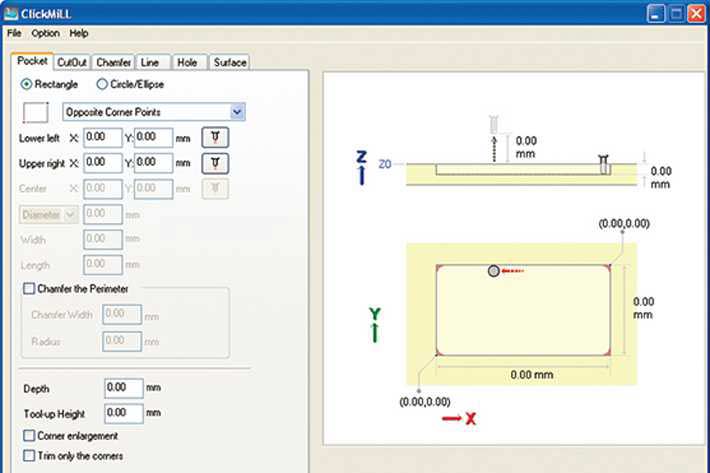

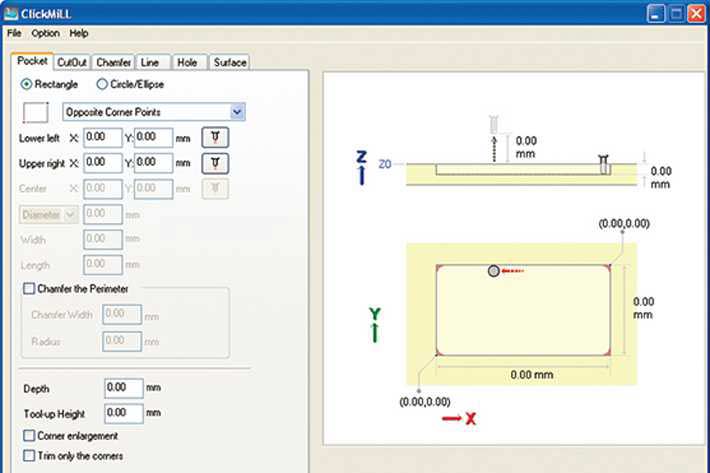

ClickMill

G Code Support

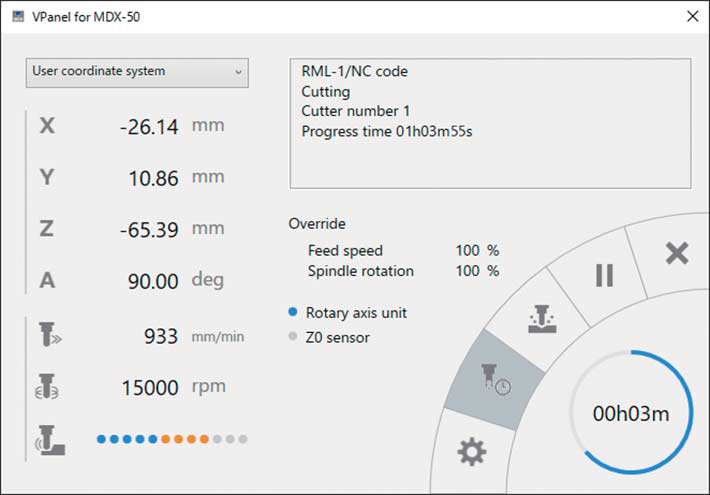

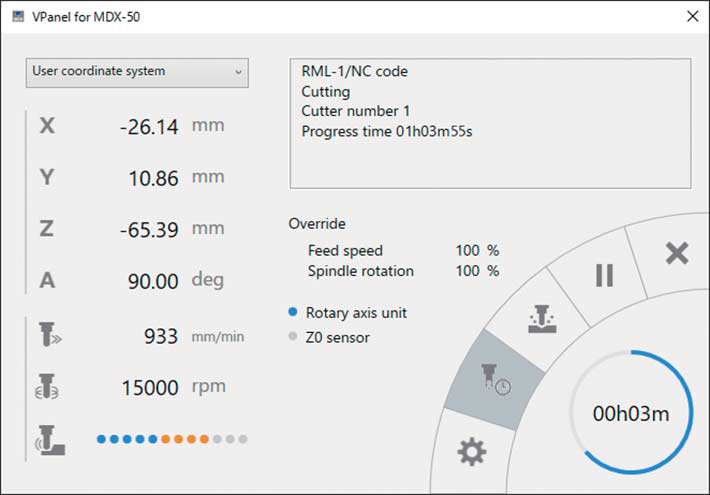

Virtual Control Panel (VPanel)

Superior Reliability and Support

Roland DG's international ISO certifications are your assurance of our commitment to quality products and service.