Here at Roland DG, we like to take all our products through their paces and explore what they’re really capable of. Packaging prototyping presents a lot of opportunities to demonstrate a wide spectrum of our products’ capabilities, so we decided to produce a bottle and box for a fictional gin brand.

To make this more interesting, and to show how easy Roland DG equipment is to use, our product specialists challenged the marketing team to produce the prototype on our own, with only limited assistance from the experts. Keep reading to find out how we got on.

Why Gin?

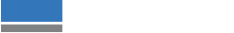

When it comes to consumer spirits, gin has seen a huge increase in popularity over the last few years. Major brands are now releasing special editions and variations of flavours, while countless micro-distilleries are popping up across the world.

Unlike other spirits, like whisky, gin doesn’t typically go through a long aging process where it’s matured in casks. Because it’s ready for sale as soon as it’s distilled, producers can more freely react to consumer trends and experiment with different blends of botanicals and flavours.

This has created a great opportunity for packaging designers and mock-up producers to create artistic and imaginative boxes and bottles which will catch the eye of gin afficionados. Even forward-thinking distilleries have brought their packaging production in-house.

Wild Distillery, a Danish micro-distiller on the island of Bornholm in the Baltic Sea, is famous for producing small batches of organic gin and vodka in a variety of flavours. They use Roland equipment to individually brand each bottle and they even offer custom designs to their customers. With personalisation continuing to be a major consumer trend, this has given them a powerful edge against their competitors.

The Aim of the Project

We could have limited ourselves to using one or two Roland DG devices to produce a packaging prototype, but for this project, we wanted to involve as many devices as possible. Here’s a quick breakdown of the technologies used:

- Cutting plotter (GR2-640) – used to cut and crease the card for the box

- UV printer/cutter (LEC2-640) – used to produce the vinyl for the box and some of the bottle labels

- Flatbed UV Printer (LEF2-300) – used to personalise bottle caps

- Flatbed UV Printer (S-Series) – used to personalise the box

Research and Design

Besides printing and producing the prototypes, we also decided to design the packaging in-house. Although we aren’t designers by trade, we thought this would give us an insight into the challenges faced by packaging designers. It also meant that we could quickly adapt the designs for different effects.

For example, to experiment with metallic vinyl, it’s necessary to print white base coats in specific areas. If we wanted to involve an external designer, we wouldn’t have the same freedom to test different approaches in a timely manner.

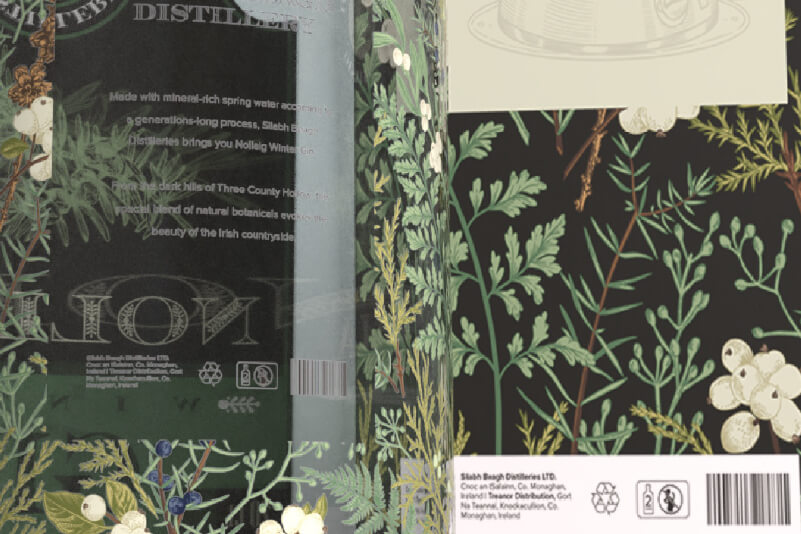

Similarly, special effects, like glossy highlights are easy enough to add when you have more control over the design process. It’s a simple matter of adding a new layer to the artwork file and assigning a specific spot colour. Although it is simple to achieve, explaining the finer points to someone unfamiliar with the technology would be time-consuming.

By taking control of the design, we could be more creative, but it left us with the challenge of developing an attractive design. We spent some time researching designs from other gin producers, and there are some amazing designs out there. Designers have innovated with quirky bottle shapes, luxurious box materials and a range of printing techniques to create truly bold and memorable bottles and boxes which really bring brands to life.

Although we won’t be winning any design awards with our signature winter gin, we’re quietly impressed with what we’ve managed to achieve!

Preparing the Design

As we were building this concept from scratch, we couldn’t rely on an off-the-shelf box template. We had to create a dieline (an industry term for a flattened template including artwork, cut lines and crease lines) for a box to fit the bottle.

Before doing this, we needed to source a bottle and use it to produce the dieline with the correct measurements. To give ourselves a margin for error, we also included cardboard inserts for the top and bottom of the bottle, holding it firmly in place.

Once the dieline was produced, we then started adding artwork. To get some indicative previews, we created a 3D render using Adobe Dimension. This was useful as it allowed us to do some initial experimentation before producing the final article.

Conclusion

Next came the time to print and assemble the box. We tackled this task in a couple of different ways – find out for yourself in the next instalment of this application challenge series.

Read More: How to Make a Folded Card Packaging Box | 3 Ways to Print Bottle Labels | How to Print Personalised Packaging

If you want to find out more about digital print solutions and how they can help businesses grow, get in touch with us and we’ll be happy to discuss your needs.