- How Roland users are creating amazing things to help protect people through the pandemic

- How to make a hands-free door opener with a Roland milling machine

- How to make a face shield with a Roland laser engraver

How Roland users are creating amazing things to help protect people through the pandemic

The past few months have been strange and challenging for all of us. We know many of our customers have been impacted, both in business and personally. But we've also seen how inventive, creative and brave the Roland community can be.

We’ve been sharing some of our favourite stories – Roland customers playing an important part in the fight against the spread of COVID-19, such as La Cocina Gráfica and Costaest who’ve been printing colourful designs on hygienic cotton face masks.

Other Roland customers have been helping to make the life easier for those on the frontline, such as Elite Signs, who produced thousands of name badges for healthcare workers and Vermeulen & Vermeulen Reclame, who have been working with a university to build ventilators, with easily readable control panels. In Turkey, Roland authorised dealer Promakim have been making parts of protective face shields with Roland LV-180 laser engravers under hygienic conditions and delivering them to health institutions.

Around the world, Roland technologies are proving to be invaluable for social distancing signage. We want to say a BIG THANK YOU to everyone who has shared photos of their Roland-made products and personal protective equipment (PPE) – please keep them coming!

Here at Roland we've also been creating a safer place to work with our own equipment. For instance, we've manufactured non-touch door openers with our MDX-540 benchtop milling machines and made face shields with our LV laser engravers. See how we made them below.

How to make a hands-free door opener with a Roland milling machine

Door handles are one of the most germ-infested objects and a prime location for COVID-19 and other nasties to linger.

This simple design means our team can open doors with their forearms rather than their hands, preventing the spread of viruses and germs.

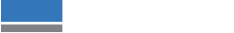

1. First, we uploaded the CAD file to the CAM software bundled with Roland’s MDX-540 milling machine.

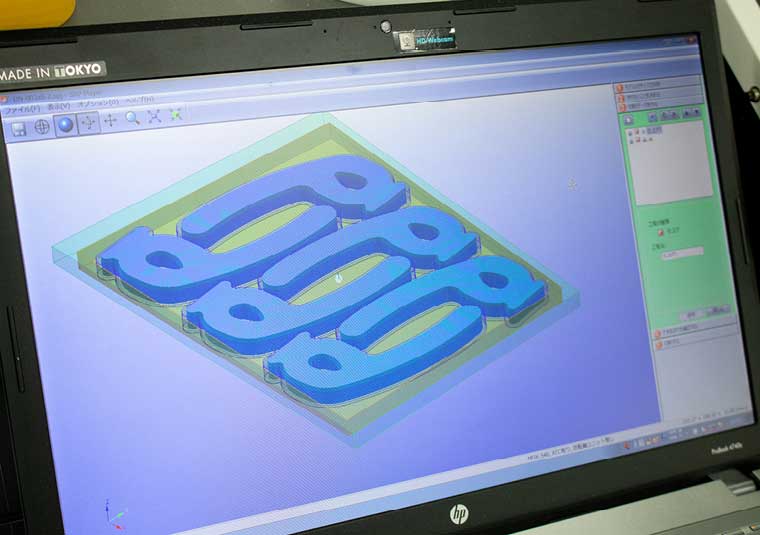

2. We placed a standard block of MDF in the machine and got milling.

3. Even producing three sets of handles at a time, the process took just a few minutes thanks to the speedy MDX-540. Once the machine has finished, the handles are ready to piece together.

4. Then, the installation: the two parts were simply slid over the door handle and joined together with an elastic band (and an anti-slip rubber sleeve, optional). We added some directional stickers, printed on the TrueVIS VG2-540 printer/cutter, and job done.

You can make your own hands-free door opener by downloading the CAD file and adjusting the shape of the hole to suit the lever of your own door.

Let us know if you try it!