When people first get into sticker printing, it’s common for them to assume that the process is straightforward. How complicated can stickers really be? While production is simple with the right sticker printing machine, there are still some considerations which can determine how successful your sticker printing business becomes.

In this article, we’ll look at some of the less-obvious factors and sticker printing secrets which can give you a real edge against your competitors. If you really want to make serious profits and become a market leader, here are some questions you should ask yourself.

Who is Buying the Sticker?

This is the first question you should ask yourself since it will guide your answers for all the other questions. Understanding your customers makes good business sense – it means that you can quickly adapt as their tastes and needs change.

On a more practical note, it lets you know how they intend to use the sticker, how they might handle the application process, how long they might expect the sticker to last, among other concerns they might have.

Where Will the Sticker Be Applied?

Are you printing small stickers to decorate and personalise objects, or is it a large wall sticker? Will it be applied indoors or on the outside of a van? Knowing these details helps you define a crucial factor: which media you need to use.

It also tells you whether the sticker should be laminated with a protective film. Naturally, this will cost more to produce and take longer, so you should ensure your sticker is priced appropriately and that you can still turn a profit.

There are other application-specific factors to consider, too. For example, if you are producing floor stickers, you’ll need to ensure that the laminate you use has a non-slip finish.

On a similar note, it’s important to understand that you don’t always need to laminate your stickers – on indoor applications, for example – so you can produce these more quickly and at a lower cost. This lets you keep the selling prices in a competitive range and attract more frugal customers.

Who Will Be Applying the Sticker?

Practically anyone can apply a small sticker to any surface without any issues. Things get complex as the stickers get larger, or the surface becomes irregular.

Again, you need to think about who your customer is. A business owner looking to brand their premises will likely expect that the wall graphics or window graphics will be installed by a professional, and their expectations of the total cost will reflect this.

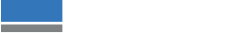

Conversely, a homeowner looking to decorate a nursery or a child’s bedroom with larger wall stickers won’t necessarily have the budget to pay for professional installation.

If you are installing the stickers, you will have the skills and the knowledge to choose the right media and apply the stickers without creases, bubbles, or other imperfections. If your customer will be applying the stickers themselves, you can’t guarantee that they’ll have those same skills, so you need to make it as easy as possible for them.

This might mean choosing a media type which is more resistant to imperfections, or which can easily be removed and replaced without destroying either the sticker or the surface. There are several solutions available, so you should ask your media suppliers for advice and learn more about the capabilities of different types of media.

Naturally, these more specialised media types will probably cost more. It won’t likely be a huge difference in price, but you should be aware of this and price your jobs appropriately, so they are still profitable.

How Long Does the Sticker Need to Last?

Novices entering the world of sticker printing might apply the same logic as they would for any other product – the longer it lasts, the more value it offers. This might be true in some cases, but if you understand who your customers are, you’ll know that stickers are not always supposed to be a permanent feature.

Some sticker applications such as retail sales promotions are only required for a short time, and in these cases, they need to meet certain criteria: they must be easy to remove without leaving any adhesive residue or causing any damage to the application surface. Again, the choice of media is important, and your print media provider can help you identify the ideal option for the job.

As for permanent stickers, you should consider where the sticker will be applied and the conditions of the space. Outdoor applications will most certainly require lamination and, regardless of its location, the adhesive of the sticker should hold it in place without slipping or peeling away over time.

What Finishes Do You Want to Offer?

So far, we’ve looked at very practical concerns for choosing the right sticker printing approach. In all the above cases, you are ensuring that your customer is not disappointed by a solution which doesn’t meet their expectations. You are effectively avoiding pitfalls and keeping your customer satisfied. But what if you could exceed those expectations and keep your customers amazed?

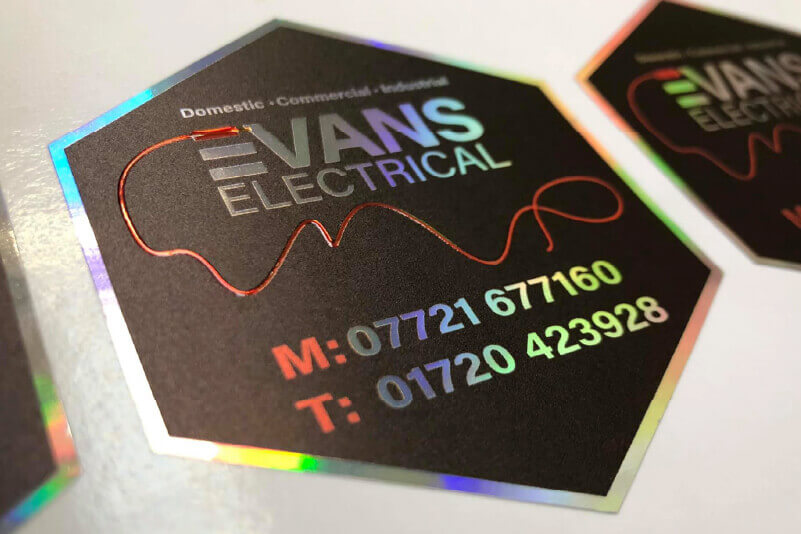

Once again, your best friend is your media supplier. Investigate the different solutions they offer, paying close attention to the more unusual media types. You can find a range of different finishes, from matte, to satin, to gloss – or even textured finishes. Outside of white media, specialist types are available like metallic, holographic, fluorescent and many more.

At this point, it’s worth considering your print capabilities and the type of ink you are using. If you want to print on non-white or transparent media, you’ll need a white ink channel to lay an opaque undercoat.

While you’re exploring your options, you could consider investing in a UV printer/cutter and including gloss ink in your ink configuration. This opens a whole range of printable effects like glossy highlights, raised textures and even Braille printing capabilities.

Conclusion

With the answers to these questions, you should know all you need to develop a professional sticker printing business and become a strong contender in the market. If you have any questions of your own, get in touch with one of our experts and they’ll do their best