DGXPRESS UG Series* UV Printer/Cutters

Combining the flexibility of print and cut, the benefits of UV-LED printing and Roland DG's renowned commitment to reliability, the DGXPRESS UG Series makes professional UV print technology accessible to businesses of all sizes.

- High-speed printing for maximum productivity.

- Highly precise print expression.

- Broad media compatibility.

- Fast drying print for quick turnaround and finishing.

- Speciality printing for textures and effects.

UV Print and Cut Solutions

Do Even More with UV Print and Cut

Enhance your capabilities with the added power of high-speed, reliable UV-LED printing technology, extensive media compatibility and speciality effects capabilities.

Everything You Need to Succeed

Choose from a variety of models and sizes to suit your business.

Power your workflow with our most intelligent engine yet.

Get stunning results every time with economical UV ink.

Keep your business going with unparalleled support.

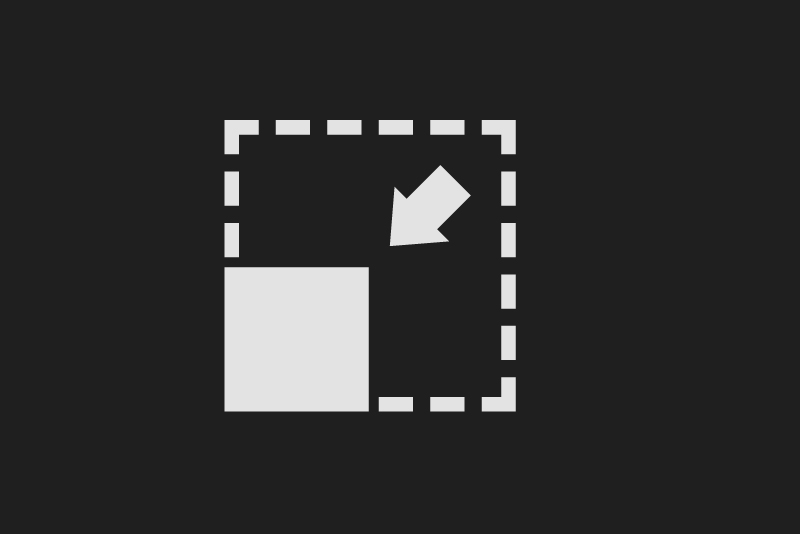

Ultimate Productivity

DGXPRESS is the ideal solution for those who need professional, reliable equipment which can exceed the demands of a thriving economy.

Every element of the DGXPRESS UV printing solution is meticulously refined to deliver high-speed output with healthy margins. With instant drying there's no need to wait for post-processing, letting you produce more and grow faster.

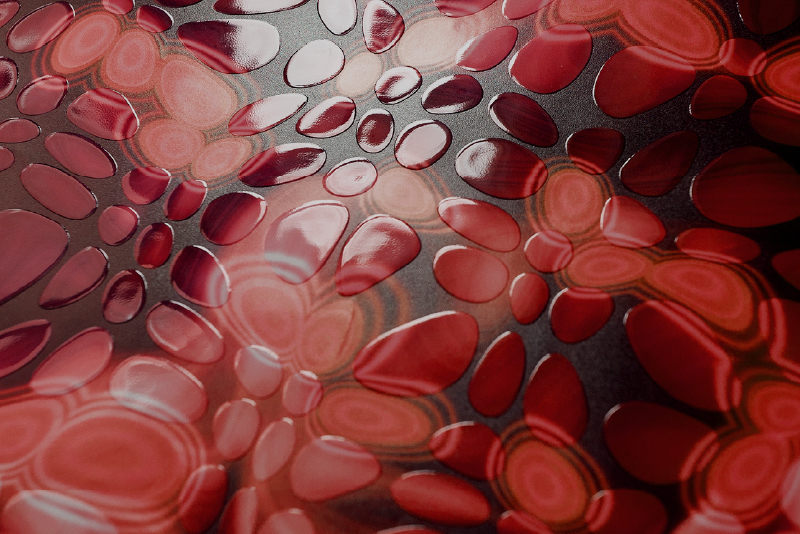

Exceptional Print Impact with Special Effects

Roland DG's UV printing solutions are crafted with precision to deliver sharp detail and stunning colour to stand out from the competition.

The addition of gloss UV ink gives you the ability to produce a wide range of special effects, further enhancing your output.

Leaders in Print and Cut

Roland DG invented print and cut technology in 1995, creating an outstanding breadth of opportunities for print professionals.

With print and cut, you can create a wide range of applications from stickers to signage, increasing your profit-making capabilities with the help of:

- Unattended operation for large quantities of stickers and labels.

- Perforation cut for faster processing after output.

High Performance Ink

Using the latest D-UA inks for high-performance and economical printing, you can get maximum speed with dual-CMYK or offer more products with the addition of White and Gloss ink.

CMYK

CMYK Get premium results with high-quality

Gloss

Generate a multitude of tangible effects, simulated embossing and gloss finishes

White

Print white details or add sub-coats for dark or transparent materials

Certifications

GREENGUARD Gold

D-UA UV inks are GREENGUARD Gold certified, meaning they meet strict standards of low chemical emissions making them ideal for indoor applications.

DGXPRESS UG-642High-performance Features

DGXPRESS UG-641Special Features

VersaWorks 6

Multifunctional RIP Suite

Besides its high-speed RIP functionality, VersaWorks 6 RIP includes a wide selection of productivity-boosting features:

- A range of built-in colour-matching functions including colour charts, finders and multi-device colour calibration.

- The Job Assistant lets you easily draw and edit cut line settings.

- The Job Variation setting quickly identifies the best print settings for

your customers' needs. - UV post-cure, and auto-generate White and Gloss layers directly in the RIP.

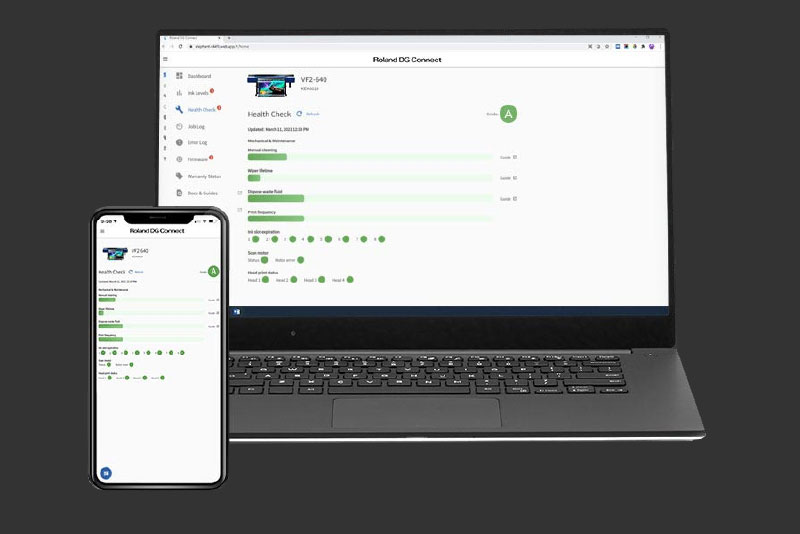

Roland DG Connect App

For Everything Creative

Reduce downtime and improve work efficiency with a machine monitoring assistant that helps you gain a detailed understanding of your entire print operation while keeping your device running at optimum performance.

Key Benefits

|

Great Return on Investment Affordable and powerful, the UG Series can generate profits and pay for itself quickly. |

|

|

Priced to Suit Your Business Roland DG UV print and cut solutions are available to fit any budget. |

|

|

Sheet Perforated Cut Separate individual jobs without cutting the backing sheet enabling unattended long runs. |

|

|

Efficient and Fluid Workflows Produce your work, your way with flexible job-management features. |

|

|

Professional Colour Management Match your customers' colour with ease thanks to advanced RIP features. |

|

|

Fast Set-up and Ease of Use Plug in and start working immediately thanks to Roland DG’s user-friendly interface. |

|

|

The Roland DG Legacy Make a safe investment with Roland DG’s world-renowned quality and reliability. |

|

|

Texture Libraries Add extra expression to your prints easily with a library full of exciting printable textures. |

|

|

Mobile Cost Tracking Track ink usage and more in real time with the Roland DG Connect mobile app. |

|

|

Media Profiles Print profiles are available and free to download for the most common media types in your area. |

Your High-Value Choice

With the release of DGXPRESS devices, you can now produce professional prints with exquisite quality at an attractive price.

Specifications

| Printing method | Piezo ink-jet method | ||||||

| Media | Width | 335 to 1625 mm |

|||||

| Thickness |

Max. 1.0 mm (39.3 mil) with liner, for printing Max. 0.4 mm (15.7 mil) with liner and 0.22 mm (8.6 mil) without liner, for cutting |

||||||

| Roll outer diameter | Max. 250 mm (9.8 in.) |

||||||

| Roll weight | Max. 45 kg (99 lb.) | ||||||

| Core diameter | 76.2 mm (3 in.) or 50.8 mm (2 in.) | ||||||

| Printing / cutting width 1 | Max. 1600 mm (62.9 in.) | ||||||

| Ink |

Type | UV-ink (D-UAP) 750ml pouch | |||||

| Colours |

Six Colours (Cyan, Magenta, Yellow, Black, Gloss, and White) Four colours (Cyan, Magenta, Yellow, and Black) |

||||||

| Ink curing unit | Built-in UV-LED lamp | ||||||

| Print resolution (dots per inch) | Max. 1200 dpi | ||||||

| Cutting speed | 10 to 300 mm/s |

||||||

| Blade force 2 | 30 to 500 gf | ||||||

| Blade | Type | Roland CAMM-1 series blade | |||||

| Offset | 0 to 1.500 mm (0 to 59 mil) | ||||||

| Software resolution (when cutting) | 0.025 mm/step (0.98 mil/step) | ||||||

| Media heating system 3 | Front heater set temperature: 30 to 55 ℃ (86 to 131 °F) | ||||||

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | ||||||

| Power-saving function | Automatic sleep feature | ||||||

| Power requirements | 100-120/220-240 Va.c. 50/60 Hz 6.5/3.2 A | ||||||

| Power consumption | During operation | Approx. 800 W | |||||

| Sleep mode | Approx. 85 W | ||||||

| Acoustic noise level | During operation |

63 dB (A) or less | |||||

| During standby | 58 dB (A) or less | ||||||

| Dimensions (with stand) | 2902 mm x 748 mm x 1412 mm |

||||||

| Weight (with stand) | 209 kg (461 lb.) | ||||||

| Environment | During operation 4 | Temperature : 20 to 32 ℃ (68 to 89.6 °F), Humidity: 35 to 80 % RH (no condensation) | |||||

| Not operating | Temperature : 5 to 40 ℃ (41 to 104 °F), Humidity: 20 to 80 % RH (no condensation) | ||||||

Depending on the ambient temperature and media width, the preset temperature may fail to be reached.

| Printing method | Piezo ink-jet method | ||||||

| Media | Width | 210 to 1625 mm |

|||||

| Thickness |

Max. 1.0 mm (39.3 mil) with liner, for printing Max. 0.4 mm (15.7 mil) with liner and 0.22 mm (8.6 mil) without liner, for cutting |

||||||

| Roll outer diameter | Max. 210 mm (8.2 in.) |

||||||

| Roll weight | Max. 40 kg (88 lb.) | ||||||

| Core diameter | 76.2 mm (3 in.) or 50.8 mm (2 in.) | ||||||

| Printing / cutting width 1 | Max. 1600 mm (62.9 in.) | ||||||

| Ink |

Type |

UV-ink (D-UA) 220ml cartridge (white) UV-ink (D-UA) 500ml cartridge (cyan, magenta, yellow, black, and gloss) |

|||||

| Colours |

Six colours(cyan, magenta, yellow, black, white, gloss) Four colours(cyan, magenta, yellow, black) |

||||||

| Ink curing unit | Built-in UV-LED lamp | ||||||

| Print resolution (dots per inch) | Max. 1440 dpi | ||||||

| Cutting speed | 10 to 300 mm/s |

||||||

| Blade force 2 | 30 to 500 gf | ||||||

| Blade | Type | Roland CAMM-1 series blade | |||||

| Offset | 0 to 1.500 mm (0 to 59 mil) | ||||||

| Software resolution (when cutting) | 0.025 mm/step (0.98 mil/step) | ||||||

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | ||||||

| Power-saving function | Automatic sleep feature | ||||||

| Power requirements | 100-240 Va.c. 50/60Hz 2.8 A | ||||||

| Power consumption | During operation | Approx. 250 W | |||||

| Sleep mode | 40 W | ||||||

| Acoustic noise level | During operation |

63 dB (A) or less | |||||

| During standby | 53 dB (A) or less | ||||||

| Dimensions (with stand) | 2819 (W) x 781 (D) x 1316 (H) mm |

||||||

| Weight (with stand) | 163 kg (360 lb.) | ||||||

| Environment | During operation 3 | Temperature: 15 to 32 °C (59 to 89.6 °F), fumidity: 20 to 80 %RH (no condensation) | |||||

| Not operating | Temperature : 5 to 40 °C (41 to 104 °F), Humidity: 20 to 80 % RH (no condensation) | ||||||

Available Accessories

Why Choose Roland DG?

People buy Roland DG equipment because they know it will do what they need it to do - and more. Our mission is to bring new opportunities to society through digital technology, and we aim to develop the most reliable solutions in the industry.

- More than 40 years of trusted technical excellence.

- Robust, flexible technology and repeatable results.

- Unparalleled post-sales service and support.

Get in touch today and find out why Roland DG is the first choice for print businesses worldwide.